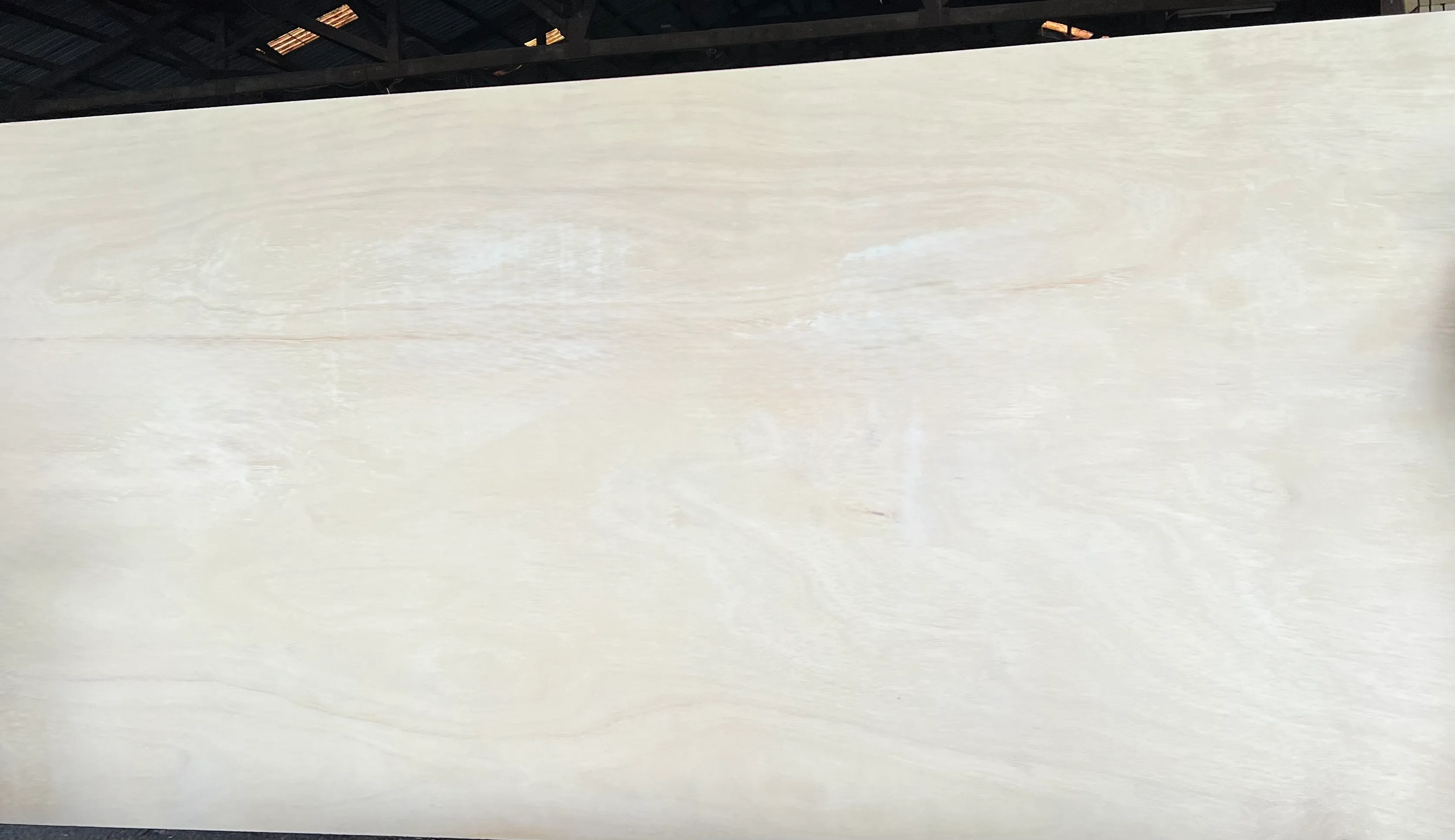

BS1088 Marine Plywood

BS1088 Marine Plywood adheres to British Standard (BS1088) specifications. It is a high quality plywood designed for marine and lasting applications, ensuring durability and resistance to water and harsh conditions.

Certification:

BS1088 : 2018 Certificate, CE : EN 13986, EPA Certificate, CARB Certificate, Sabah - TLAS Certificate, PEFC (Upon Request)

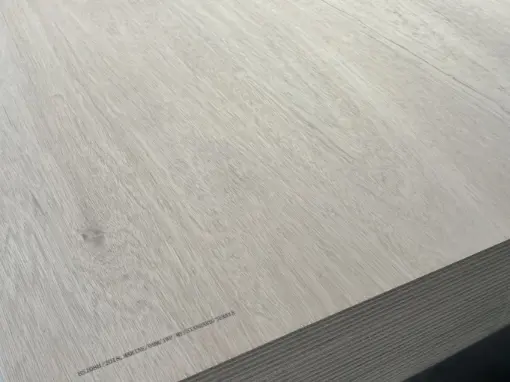

Flooring Plywood

Flooring plywood is a premium quality plywood renowned for its durability, strength and exceptional performance as underlayment. It is manufactured using high mechanical strength wood species and advanced adhesive technology, ensuring resistance to moisture, warping and pest infestation.

Certification:

UKCA, CE : EN 13986, EPA Certificate, CARB Certificate, Sabah - TLAS Certificate, PEFC (Upon Request)

Flexiply

Flexiply offers high degree bending capabilities in either the long grain or short grain direction. Panels can be rolled to a diameter of 450mm.

Certification:

EPA Certificate, CARB Certificate, Sabah - TLAS Certificate, PEFC (Upon Request)

Structural Laminated Veneered Lumber (S-LVL)

Structural Laminated Veneered Lumber (S-LVL) is a high performance engineered wood product comprised of purposely designed veneer configuration bonded under controlled conditions with high strength adhesives, yielding a dimensionally stable, uniformly strong structural material ideal for load bearing applications.

Certification:

EPA Certificate, CARB Certificate, Sabah - TLAS Certificate, PEFC (Upon Request)

Japanese Standard Plywood

Japanese Agricultural Standard (JAS) Plywood is manufactured with standardised protocol set by MAFF* of Japan ensuring that all key steps of plywood production and the parameter of equipment is sufficiently checked, self testing procedures are in place and the samples of the self testing are critically verified by third party auditor

Certification:

UKCA, JAS CP : Concrete Panel - Type 1, MUF, JAS CP : Concrete Panel - Type Special, Phenolic WBP, JAS SP : Structural Panel - Type Special, Phenolic WBP, JAS OP : Ordinary Panel, Sabah - TLAS Certificate, PEFC (Upon Request)

CE Standard Plywood

CE Standard refers to the production of panels which are guided by a series of European standards: EN 13986, EN 636, EN 314 & EN 350 etc. It ensures a comprehensive scrutiny on almost all aspects of theproduction of plywood and provide an objective reporting framework on the classification of different parameters such as bonding, strength e.g. MOE, MOR, formaldehyde emission and the natural durability of the product etc. Furthermore it ensures the production system and the quality control tools are sufficiently verified and the reporting procedure of self test are adequately enforced. CE Standard plywood are widely used in construction, furniture and industrial applications.

Certification:

CE : EN 13986, EPA Certificate, Sabah - TLAS Certificate, PEFC (Upon Request)

IHPA Standard

IHPA Standard refers to the guidelines set by the International Hardwood Products Association (IHPA), now known as the International Wood Products Association (IWPA). It focuses on hardwood plywood and veneer. It is intended for furniture and interior application.

Certification:

IWPA, EPA Certificate, CARB Certificate, Sabah - TLAS Certificate, PEFC (Upon Request)

Kiln Dried veneer

Face : 1.3 x 910 x 1820mm, NWP, Mixed Wood, Seraya

Back / LGC : 1.3 x 910 x 1820mm, NWP / JWP, Mixed Wood, Seraya

SGC : 1.5, 1.8, 2.6 x 910 x 1820mm, NWP / PPC, Mixed Wood,Seraya

Face : 0.6 x 1220 x 2440mm, NWP, Seraya

Back : 0.6 x 1220 x 2440mm, NWP/JWP, Seraya

LGC : 1.6, 2 x 1220 x 2440, 1250 x 2500mm, NWP / PPC, RubiaWood,Seraya

SGC : 1.6, 2 x 1220 x 2440mm, 1250 x 2500, NWP / PPC, RubiaWood,Seraya

Certification:

Sabah - TLAS Certificate

Solid

Density 450 –550kg/m³ at MC 12

Medium hard & Hard species group

Density 550 –750kg/m³ at MC 12

2. Pallet

3. Railway Slipper

4. Sangi

5. Decking

Certification:

Sabah - TLAS Certificate, ISPM 15, PEFC (Upon Request)

Moulding

1. Solid Laminated Board

2. Fingerjoint Laminated Board

3. Finger Stick

Certification:

EPA Certificate, CARB Certificate, Sabah - TLAS Certificate, ISPM 15, PEFC (Upon Request)